Chiedi a un esperto

Testing & Troubleshooting

- Home

- Servizi

- Soluzioni tecniche

- Testing & Troubleshooting

We have offered consultative technical services to our customers since our founding. These services cover material selection, part design, tooling evaluations, process development and troubleshooting, equipment recommendations, production validation, and testing, etc. Regardless of the need, we are there every step of the way.

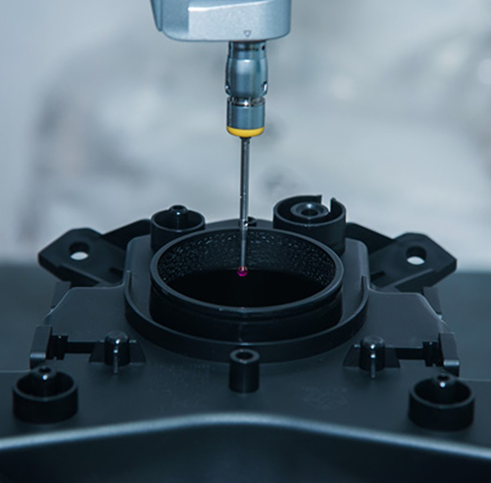

Testing of the end product (or components) is necessary to confirm the material selected, part design, and manufacturing process will collectively deliver the performance requirements of the application. See also testing during Material Selection.

For testing, we provide:

Are you encountering challenges during your production process? Our highly skilled technical representatives can assist with on-site troubleshooting to identify and address any manufacturing issues that may be contributing to poor quality or process efficiencies. We use tools and techniques that include gathering and evaluating hard data, not just theories.

For troubleshooting we provide:

Using our technical solutions team for evaluating and troubleshooting your process will alleviate associated stress and can save you time and money.

Our technical team is available online or in person to support you wherever you are in your application development process.