Richiedi un preventivo

TPE Elexar®

- Home

- Prodotti per fornitori

- Teknor Apex

- TPV Elexar

Progettato per elevate prestazioni

Grazie alle loro robuste proprietà, alla convenienza economica e alle opzioni di progettazione, gli elastomeri termoplastici, o TPE, sono la prima scelta per i materiali morbidi e flessibili. In quanto leader globale nella compoundazione, Teknor Apex offre uno dei più ampi portafogli di tecnologie TPE del settore, tra cui compound di copolimero stirenico a blocchi (SBC), miscele poliolefiniche (TPE-O o TPO), termoplastici vulcanizzati (TPE-V o TPV), compound poliuretanici (TPE-U o TPU) e altre miscele speciali.

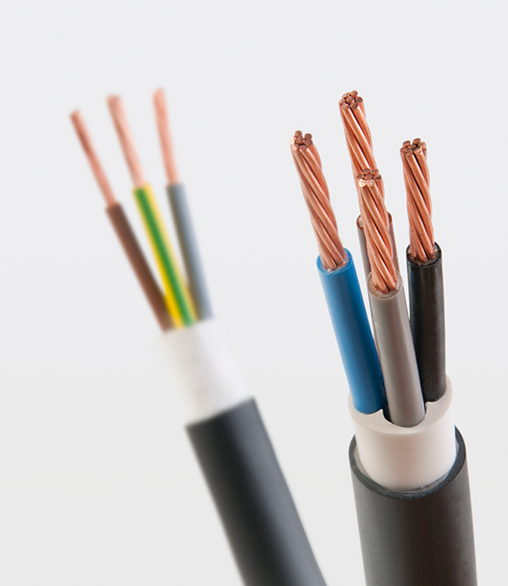

Elexar® è la soluzione per eccellenza per la scelta di materiale nella progettazione di cavi e altri prodotti elettrici per ambienti difficili o a basse temperature. Oltre ad avere proprietà elettriche eccezionali, i TPE Elexar® sono stabili ai raggi ultravioletti, resistenti all’abrasione e alle sostanze chimiche, e mantengono la loro flessibilità anche a temperature estreme. I TPE Elexar® sono disponibili con o senza ritardanti di fiamma, sono certificati dalla carta gialla dei laboratori UL, e risultano conformi alle normative RoHS e REACH per le sostanze SVHC.

Adottando un approccio più focalizzato per soddisfare le esigenze di ogni mercato, il portafoglio di prodotti TPE di Teknor Apex è allineato con i settori di applicazione. Le qualità standard spesso soddisfano le normative applicabili e le specifiche per il settore in questione. Di conseguenza, i compound TPE di Teknor Apex possono essere prequalificati per la tua applicazione, il che può accelerare la tempestività di commercializzazione di nuovi prodotti. Caratteristiche e proprietà che presentano le linee di prodotti Elexar®:

I TPE Elexar® offrono una combinazione unica di flessibilità, tenacità e resistenza all’abrasione per le parti esposte ad ambienti difficili. Generalmente adatti sia per estrusione sia per stampaggio a iniezione, questi materiali versatili possono essere utilizzati per l’isolamento e rivestimento di fili e cavi, spine e connettori elettrici, serracavi e passacavi. Alcune delle applicazioni tipiche includono:

|

|

|

TPS EL-8431 NAT ELEXAR |

|

TPS EL-8730R NAT ELEXAR |

|

TPS EL-1934E NAT ELEXAR |

|

TPS EL-8730R BK ELEXAR |

|

TPS EL-8431 BK ELEXAR |

|

TPS EL-1934G NAT ELEXAR |

|

TPS EL-1934F NAT ELEXAR |