Eccellente stabilità dimensionale e tolleranza alle alte temperature

Il PPS (solfuro di polifenilene) Ryton® è una famiglia di polimeri semicristallini con eccellente stabilità dimensionale e tolleranza alle alte temperature. Questo polimero ad alte prestazioni inerentemente ritardante di fiamma presenta un’eccezionale resistenza chimica rispetto ai fluoropolimeri e PEEK di riferimento.

Con una combinazione unica di proprietà e un equilibrio ottimale di costi e prestazioni, il PPS Ryton® offre una serie incredibile di prestazioni e vantaggi di lavorazione per varie applicazioni. Il PPS Ryton® è un materiale altamente efficiente che offre eccellente resistenza chimica, prestazioni termiche, resistenza allo scorrimento e flessibilità di progettazione.

I compound in PPS (solfuro di polifenilene) Ryton® offrono una combinazione unica di proprietà e un equilibrio tra costi e prestazioni ineguagliabile rispetto ad altri materiali termoplastici tecnici. Caratteristiche e proprietà che presentano le linee di prodotti Ryton®:

|

|

I polimeri ad alte prestazioni PPS Ryton® sono ottimali per diversi elettrodomestici, grazie alla loro combinazione di lavorabilità e prestazioni. Il PPS Ryton® consente agli OEM di elettrodomestici di rispondere alle esigenti tendenze di mercato, generando al contempo opportunità di risparmio sui costi rispetto all’uso di metalli tradizionali, termoindurenti e altri materiali ingegneristici.

Alcune delle applicazioni tipiche includono:

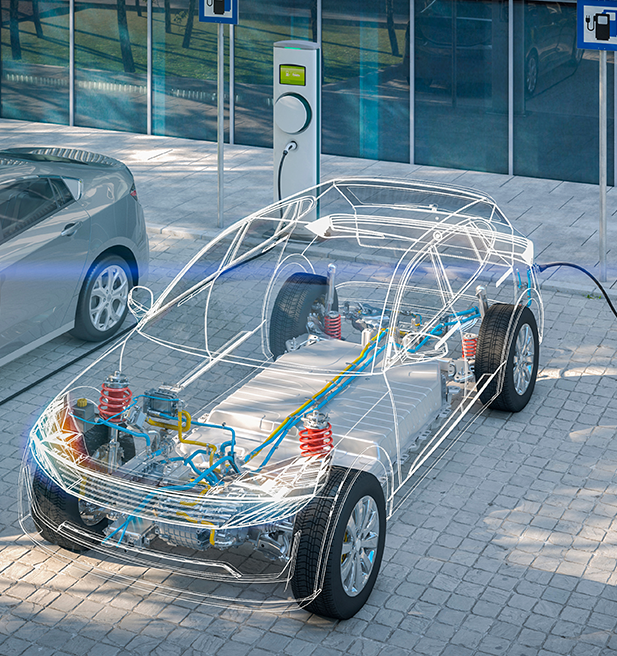

Grazie alla sua capacità di sopportare le alte temperature, fluidi per auto e sollecitazioni meccaniche significative, il PPS Ryton® è un materiale preferito in un’ampia gamma di applicazioni e componenti automobilistici. Il polimero ad alte prestazioni funge da alternativa ideale ai metalli, in quanto è più leggero, resistente a fluidi e sali corrosivi, e offre capacità di progettazione ottimali.

Alcune delle applicazioni tipiche includono:

Il PPS Ryton® offre eccezionale valore per applicazioni di componenti elettrici ed elettronici, in quanto vanta un eccellente flusso e basso ritiro per lo stampaggio di precisione, rigidità superiore e integrità meccanica per l’assemblaggio, e buona stabilità per metodi di saldatura SMT.

Alcune delle applicazioni tipiche includono:

Grazie alla sua rinomata stabilità termica, meccanica, dimensionale e chimica, il PPS Ryton® è utilizzato in un’ampia gamma di applicazioni e componenti a idrogeno verde. Dotato di eccezionale leggerezza e integrità meccanica unica, il PPS Ryton® offre ottima flessibilità di progettazione per innovazioni rivoluzionarie nel settore dell’economia a idrogeno verde.

Alcune delle applicazioni tipiche includono:

Il PPS Ryton® offre agli OEM industriali una combinazione vincente di proprietà, in particolare per componenti e applicazioni di stampaggio a iniezione. Grazie alla straordinaria stabilità termica, elevata resistenza chimica e lunga durata, il PPS Ryton® è particolarmente adatto per garantire elevate prestazioni anche in condizioni e ambienti ostili.

Alcune delle applicazioni tipiche includono:

|

PPS R-7-120BL BK RYTON |

PPS R-4-240NA NAT RYTON |

PPS V-1 NAT PWD RYTON |

|

PPS R-4-220BL BK RYTON |

PPS R-4-220NA NAT RYTON |

PPS R-4-230NA NAT RYTON |

|

PPS R-4-200BL BK RYTON |

PPS R-4 NAT RYTON |

PPS R-7-220BL BK RYTON |

|

PPS R-4-02XT BK RYTON |

PPS XK2340 BK RYTON |

PPS BR111 NAT RYTON |

|

PPS R-4-200NA NAT RYTON |

PPS XE3035NA NAT RYTON |

PPS R-4-230BL BK RYTON |

|

PPS BR42B NAT RYTON |

PPS XE5030BL BK RYTON |

PPS XE5500BL BK RYTON |

|

PPS R-7-120NA NAT RYTON |

|

|