Scegli la tua lingua

Richiedi un preventivo

Poliolefine termoplastiche (TPO)

- Home

- Prodotti per fornitori

- RheTech

- Poliolefine termoplastiche (TPO)

La poliolefina termoplastica, o TPO, è una combinazione di poliolefine come il polipropilene e il polietilene, modificatori antiurto e riempitivi minerali come talco e fibre di vetro. Le poliolefine termoplastiche (TPO) sono disponibili in una varietà di qualità in base a rigidità, equilibrio antiurto, colorabilità, stabilità ai raggi ultravioletti e resistenza alla fiamma.

Le poliolefine termoplastiche di RheTech sono note per il loro consolidato impegno a garantire un livello di alta qualità, opzioni estese di personalizzazione per soddisfare requisiti specifici, assistenza tecnica efficiente e soluzioni convenienti che possono ottimizzare i tuoi processi di produzione mantenendo gli standard prestazionali. La dedizione di RheTech al controllo di qualità garantisce la coerenza delle sue TPO, il che le rende ideali per diverse applicazioni, dai pezzi automobilistici ai beni di consumo.

Le poliolefine termoplastiche (TPO) Rhetech offrono una gamma completa di caratteristiche e proprietà che le rendono altamente desiderate per applicazioni che richiedono durata, resistenza ai raggi ultravioletti, resilienza agli urti e capacità di lavorazione versatili. Che la tua azienda operi nel settore automobilistico, edile o dei prodotti da esterno, le TPO Rhetech offrono l’affidabilità e le prestazioni necessarie per i tuoi progetti. Ecco alcune caratteristiche e proprietà della linea di prodotti.

La straordinaria durata e facilità di lavorazione delle TPO Rhetech le rendono un materiale preferito nel settore edile. Sono comunemente utilizzate in membrane per tetti, rivestimenti e materiali per terrazzamento o piani di calpestio, in cui la resistenza alle radiazioni UV e agli agenti atmosferici garantisce longevità e pochi interventi di manutenzione. Alcune delle applicazioni tipiche includono:

Grazie alla loro eccezionale durata e resistenza alle radiazioni UV, le poliolefine termoplastiche (TPO) Rhetech sono una scelta eccellente per il mercato dei beni di consumo. Questi materiali mantengono il loro aspetto e integrità strutturale anche all’aperto, il che le rende ideali per prodotti di consumo da esterno come mobili da giardino e attrezzature per il tempo libero. Le applicazioni comuni possono includere:

Grazie alla loro durata, struttura leggera ed eccezionale resistenza agli agenti atmosferici, le poliolefine termoplastiche (TPO) Rhetech sono particolarmente adatte per il settore dei veicoli ricreativi (RV). Questi materiali consentono di ridurre il peso del veicolo, incrementare il risparmio di carburante e mantenere l’estetica nel tempo. Alcune delle applicazioni tipiche includono:

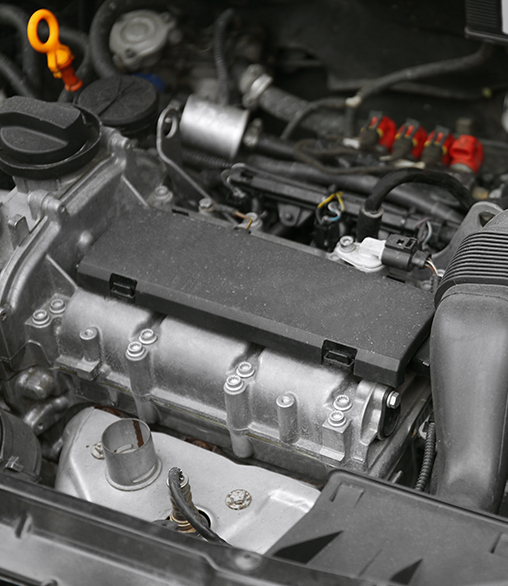

Nel mercato della mobilità, le TPO Rhetech si distinguono per la loro maggiore resistenza agli urti e versatilità nella lavorazione. Sono perfette per la produzione di componenti automobilistici esterni come paraurti, pannelli per carrozzeria e finiture, garantendo sia sicurezza che attrattiva estetica. Alcune delle applicazioni tipiche includono:

Grazie alla loro eccezionale durata e resistenza alle radiazioni UV, le poliolefine termoplastiche (TPO) Rhetech sono una scelta eccellente per il mercato dei beni di consumo. Questi materiali mantengono il loro aspetto e integrità strutturale anche all’aperto, il che le rende ideali per prodotti di consumo da esterno come mobili da giardino e attrezzature per il tempo libero. Le applicazioni comuni possono includere:

|

TPO FT7011 01UV BK |

TPO FT1045 1118UV BK |

TPO FT5050 1181UV GY |

TPO FT3080 50 BK |

|

TPO FT5050 1061UV GY |

TPO FT3250 1117UV BK |

TPO FT5086 01 BK |

TPO FT5070 01 BK |

|

TPO FT5050 1023UV GY |

TPO FT5050 1021UV BN |

TPO FT5090 1147UV |

TPO FT5100 01UV BK |

|

TPO FT5050 1109UV BK |

TPO FT1036 01 BK |

TPO FT3150 01 BK |

TPO FT1045 1118UV BK |

|

TPO FT1045 01UV NAT |

TPO FT3250 1060UV GY |

TPO FT5050 1181UV GY |

TPO FT7030 01UVEG BK |

|

TPO FT3120 01UV BK |

TPO FT5050 1093UV GY |

TPO FT3250 1117UV BK |

|