Richiedi un preventivo

Ultramid® Advanced

- Home

- Prodotti per fornitori

- BASF

- Ultramid® Advanced

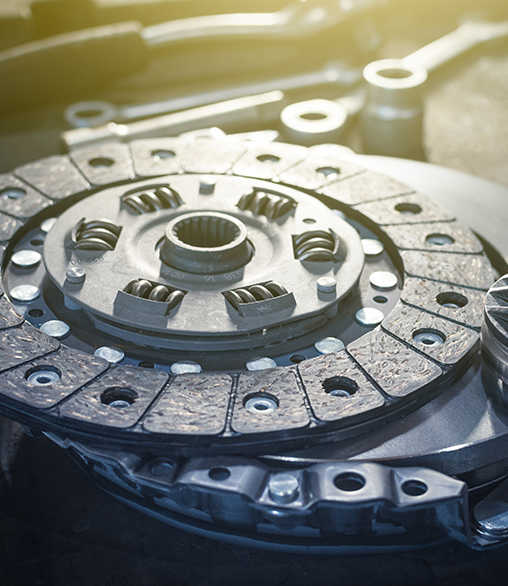

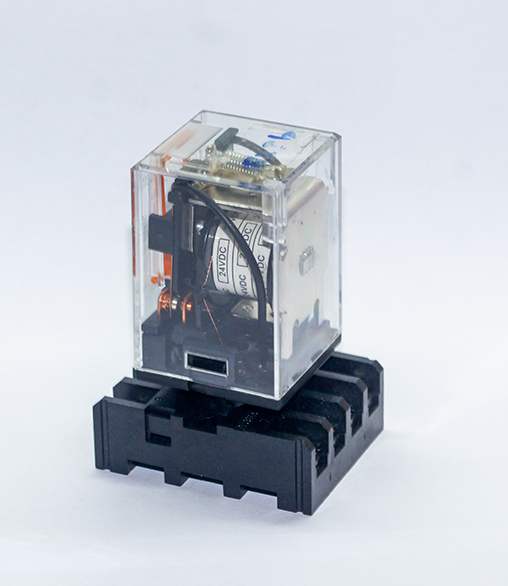

Dal settore automobilistico a quello dei componenti elettrici ed elettronici, dell’ingegneria meccanica e dei beni di consumo, i polimeri Ultramid® Advanced sono progettati per applicazioni ad alte prestazioni. Il nuovo portafoglio di poliftalammidi (PPA) Ultramid® Advanced di BASF comprende cinque polimeri con circa 50 compound. Ampiamente utilizzati come alternativa al metallo, i polimeri Ultramid® Advanced consentono maggiori opzioni di progettazione, costi inferiori e riduzione del peso rispetto alle parti realizzate in metallo.

I compound per stampaggio Ultramid® Advanced sono disponibili non rinforzati o rinforzati con minerali, fibre di vetro lunghe o corte oppure fibre di carbonio per applicazioni speciali. Queste poliftalammidi sono note per la loro elevata resistenza meccanica, rigidità e stabilità termica. Inoltre, Ultramid® Advanced offre buona compattezza a basse temperature, presenta un comportamento positivo di attrito radente ed è facilmente lavorabile. Questi polimeri PPA sono realizzati per sopportare elevate temperature pur mantenendo la loro tenacità, anche nei processi di saldatura senza piombo in una serie di settori.

Grazie alla personalizzazione e alle loro proprietà meccaniche e termiche ad alte prestazioni, i materiali PPA Ultramid® Advanced possono essere utilizzati per diverse applicazioni. Le applicazioni includono il settore automobilistico e mobilità, componenti elettrici ed elettronici, edilizia, mobili, sanitari e molto altro. Inoltre, Ultramid® Advanced può essere lavorato in una varietà di metodi tra cui estrusione e stampaggio a iniezione.

Il portafoglio Ultramid® Advanced include tipologie con le seguenti opzioni:

Ecco le caratteristiche e proprietà delle linee di prodotti Ultramid®:

La poliammide 9T (PA9T) Ultramid® Advanced N è dotata di proprietà meccaniche costanti fino a 100 °C (temperatura di transizione vetrosa: 125 °C), straordinaria resistenza chimica, basso assorbimento dell’acqua ed eccellenti proprietà tribologiche. Le applicazioni tipiche includono:

La poliammide T1000 6T/6I (PA6T/6I) è il gruppo di prodotti con la tenacità e rigidità più elevate della famiglia Ultramid® Advanced. Le poliftalammidi T1000 vantano proprietà meccaniche stabili a temperature fino a 125 °C (asciutte) and 80 °C (condizionate). Offrono elevata resistenza all’umidità e a supporti aggressivi, superando di gran lunga le prestazioni delle poliammidi tradizionali e di molti altri materiali PPA sul mercato. Alcune delle applicazioni tipiche includono:

Ultramid® Advanced T2000 è la soluzione ideale per pezzi che richiedono rigidità e tenacità elevate e costanti in un’ampia gamma di temperature, resistenza a calore e umidità, nonché proprietà opzionali di resistenza alla fiamma (FR). Le applicazioni comuni possono includere:

Ultramid® T KR è stata tra le prime PPA sul mercato. Questa poliammide 6T/6 (PA6T/6) ha un punto di fusione elevato di 295 °C ed è facile da lavorare. Offre elevata rigidità e tenacità, specialmente in presenza di umidità o alte temperature, e allo stesso tempo vanta la tenacità più elevata tra tutti i materiali PPA. Ultramid® T KR possiede un’eccellente resistenza al calore: L’indice di traccia relativo (RTI) di 160 °C a 0,4 mm di Ultramid® T KR4340 G6 è uno dei più elevati RTI sul mercato delle poliammidi. Alcune delle applicazioni tipiche includono:

Ultramid® One J è una poliammide resistente alle alte temperature con prestazioni migliori della PA66 in termini di proprietà dielettriche e meccaniche, in particolare in presenza di umidità e temperature elevate. Questa poliammide 66/6T (PA66/6T) vanta un’elevata fluidità e facilità di lavorazione al pari della PA66, e le sue eccellenti proprietà meccaniche rimangono inalterate dalle temperature di stampaggio. Ultramid® One J offre nuove possibilità di colorazione con le tonalità di bianco per pezzi miniaturizzati con protezione elettrica. Le carte UL ne certificano l’eccellente RTI e GWIT; inoltre, il ritardante di fiamma utilizzato è privo di alogeni. Alcune delle applicazioni tipiche includono: