Richiedi un preventivo

Ultramid®

- Home

- Prodotti per fornitori

- BASF

- Ultramid®

Il portafoglio di materie plastiche ingegneristiche Ultramid® di BASF include decine di gradi di compound poliammidici per lo stampaggio basati su PA6, PA66, PA610 e diversi copoliammidi tra cui PA66/6. La gamma inoltre include il portafoglio specializzato Ultramid® Advanced di poliftalammidi semiaromatiche ad alte prestazioni come PA6T/6, PA6T/66, PA6T/6I e PA9T.

Scopri di più su Ultramid® Advanced

Le poliammidi Ultramid® sono note per la loro elevata resistenza meccanica, rigidità e stabilità termica. Inoltre, Ultramid® offre buona compattezza a basse temperature, comportamento positivo di attrito radente e facile lavorabilità. I compound per stampaggio Ultramid® sono disponibili non rinforzati, rinforzati con fibre di vetro o minerali, oltre a rinforzati con fibre di vetro lunghe per applicazioni speciali.

La poliammide (PA) Ultramid® può essere utilizzata per molte applicazioni grazie alle sue caratteristiche versatili e personalizzabili. Le applicazioni includono il settore automobilistico e mobilità, componenti elettrici ed elettronici, edilizia, mobili, sanitari e molto altro. Inoltre, Ultramid® può essere lavorata in una varietà di metodi tra cui estrusione e stampaggio a iniezione. Ecco alcune caratteristiche e proprietà delle linee di prodotti Ultramid®:

I gradi Ultramid® per elettrodomestici offrono qualità ritardanti di fiamma ed elettroniche. La loro elevata tenacità, le buone prestazioni meccaniche e la resistenza chimica sono ideali per tale mercato. Inoltre, le poliammidi possono essere rese trasparenti e traslucide ed essere dotate di proprietà antigraffio e di brillantezza. Alcune delle applicazioni tipiche includono:

Per decenni, BASF è stato un leader riconosciuto nello sviluppo di materiali e componenti complessi per il settore automobilistico a livello mondiale. Le materie plastiche ingegneristiche Ultramid® offrono un’eccellente stabilità dimensionale e resistenza all’usura, anche quando sono esposte a temperature elevate, raggi ultravioletti e condizioni meteorologiche estreme. Alcune delle applicazioni tipiche includono:

Le poliammidi Ultramid® sono materie plastiche ingegneristiche fenomenali, dotate di maggiore resistenza e più leggere dell’acciaio. Il portafoglio di Ultramid® include qualità che soddisfano le specifiche tecniche e i requisiti relativi alla salute e sicurezza per applicazioni idriche e sanitarie. Le applicazioni comuni possono includere:

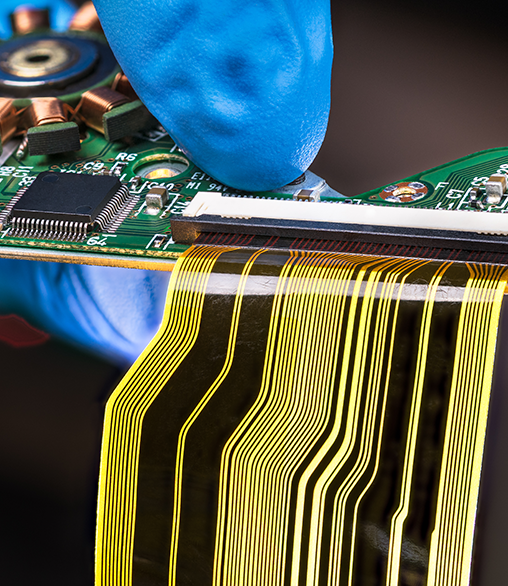

Per quanto riguarda le termoplastiche nei mercati dei componenti elettrici ed elettronici, è presente una domanda crescente per componenti sempre più piccoli che sono ritardanti di fiamma e offrono prestazioni migliori. Le qualità Ultramid® possiedono eccellenti proprietà elettriche, caratteristiche meccaniche e resistenza al calore. Alcune delle applicazioni tipiche includono:

L’elevata resilienza meccanica combinata all’ottima tenacità rende Ultramid® una scelta eccellente per molte applicazioni nel settore dei mobili, in cui materiali tradizionali come il metallo o il legno possono essere sostituiti da plastiche con proprietà personalizzate. Alcune delle applicazioni tipiche includono:

Gli elettroutensili devono essere durevoli, efficienti e dotati di prestazioni eccellenti. La scelta dei materiali svolge un ruolo chiave nel determinare se un elettroutensile può superare il test di durata. Le poliammidi Ultramid® offrono elevata rigidità, eccellente resistenza agli urti, proprietà ritardante di fiamma e ottima resistenza ai fluidi. Le materie plastiche Ultramid® sono un ottimo sostituto per parti metalliche specifiche, il che rende gli strumenti più leggeri e facili da utilizzare. Alcune delle applicazioni tipiche includono:

|

PA6 8202 NAT ULTRAMID |

||

|

PA6 8202 WT6407 ULTRAMID |

PA6 8267GHS BK106 ULTRAMID |

|

|

PA6 8267GHS NAT ULTRAMID |

PA6 B3GM35 Q649 BK23220 ULTRAMID |

|

|

PA6 8202CHS GY7470 ULTRAMID |

PA6 8333GHIHS BK102 ULTRAMID |

PA6 B3M8 NAT ULTRAMID |

|

PA6 8202HS BK102 ULTRAMID |

||

|

PA6 8202L NAT ULTRAMID |

PA6 B3WGM24 BK30564 ULTRAMID |

|

|

PA6 8233G NAT ULTRAMID |

PA66 1503 2 ND3007 BK ULTRAMID |

|

|

PA6 8233GHS BK102 ULTRAMID |

||

|

PA6 8233GHS BK106 ULTRAMID |

||

|

PA6 8233GHS NAT ULTRAMID |

PA6 B3G7R01 RD7920 ULTRAMID |

|

|

PA6 B3GM35 EBONY23227 ULTRAMID |